Proven Excellence in Customer Satisfaction and Environmental Quality Management. GRP water tank is made from the finest materials to ensure top product quality and customer satisfaction.

The glass fibre reinforced panel is moulded under high temperature and pressure conditions to maintain the best endurance.

Using stainless steel for the interior structure and plated steel for the exterior, the panel exhibits excellent resistance to erosion.

As the surface of GRP panel is even and smooth, sediment deposits do not form and corrosion does not occur. In addition, external light is fully blocked and any propagation of bacteria or various germs is inhibited, making hygienic use over long time periods possible.

GRP Sectional water tanks has several advantages in comparison with normal conventional tanks.

- Various capacity designs

- Excellent hygienic

- Best size stability

- Easy to assemble & moving

- No leakages

- Durable & aesthetic appeal

- Insulated panels allows no heat transfer

- Economical & effective for maintenance

- Space utilization by partition

- Chemically inert with commercial chemicals

- Tailor maid tanks to fit the available space

- Level gauges to see the level of the water

- Inspection windows can be provided for inspection

- High strength panels

Specification of SMC GRP Sectional Water Tanks

The panels are made of the state-of-the-art compound material (suitable to store portable water/filtered water) GRP (Glass Reinforcement Plastic), which is a combination of unsaturated polyester resin (ISM 3305) with a filter, catalyst, isomer, etc. made from non-alkaline glass fibre (KSL 2327, 2508, 2313). This material is high-temperature and high-pressure moulded and is non harmful to drinking or consumption.

GRP Panel Physical Properties

Tensile Strength: more than 60 Mpa

Barcol Hardness: more than 30

Flexural Strength: More than 80 Mpa

Glass Fibre Content: more than 25%

Flexural Modules: more than 6000 Mpa

Test Method: Based on KSF – 4811

Thickness: Upper panel: 3.5, Side Panel: 6.0 - 7.5, Lower Panel: 6.5 – 7.5

Sealant: Non Toxic, hygienic, unchanging in high temperature, made from a PVC – type material that is as durable as the panels, and easy to apply like tape.

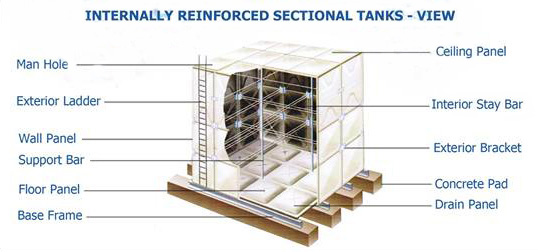

Stiffener and Bracket:

Interior: Stainless Steel

Exterior: Iron Steel Treated with Hot Zinc Dipping

Each bracket and connected interior stiffener must be installed to be strong enough so as to not undergo any sort of distortion.

Bolts and Nuts: According to KS standards, the bolts must be of 10mm or more in diameter. Those for interior use must be SUS 304 or higher, and those for exterior use must be zinc plated.

Ladder: Sufficiently sturdy in terms of load – carrying and adhesive power and be hygienically non harmful. The interior ladder must be of SUS material and the exterior ladder must be made of iron steel plated with hot-dipped zinc.

Vent: made as a grill (SUS 304, Bronze) inserted with VC material (coating).

Manhole: Interior maintenance feasible.

Foundation Frame: Iron steel treated with hot zinc dipping